The Art And Science Of Jewellery Manufacturing: A Comprehensive Guide

The Art and Science of Jewellery Manufacturing: A Comprehensive Guide

Related Articles: The Art and Science of Jewellery Manufacturing: A Comprehensive Guide

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Art and Science of Jewellery Manufacturing: A Comprehensive Guide. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Art and Science of Jewellery Manufacturing: A Comprehensive Guide

Jewellery, a timeless expression of artistry and craftsmanship, transcends mere adornment. It embodies cultural significance, personal narratives, and enduring value. The creation of this exquisite art form rests upon the shoulders of jewellery manufacturers, who transform raw materials into breathtaking pieces that captivate hearts and adorn lives. This comprehensive guide delves into the intricate world of jewellery manufacturing, unraveling its multifaceted processes, exploring its significance, and outlining the crucial role it plays in shaping the global jewellery industry.

Understanding the Jewellery Manufacturing Process

Jewellery manufacturing is a multi-faceted process that involves a meticulous blend of artistry, technical expertise, and meticulous attention to detail. The journey from raw materials to finished pieces unfolds through a series of distinct stages, each demanding specialized skills and advanced equipment.

1. Sourcing and Selection of Raw Materials:

The foundation of any exquisite piece of jewellery lies in the quality of its raw materials. Jewellery manufacturers meticulously source precious metals like gold, silver, and platinum, along with gemstones, pearls, and other materials, ensuring their authenticity, purity, and ethical sourcing. This stage involves rigorous quality checks and certifications to guarantee the integrity and sustainability of the materials used.

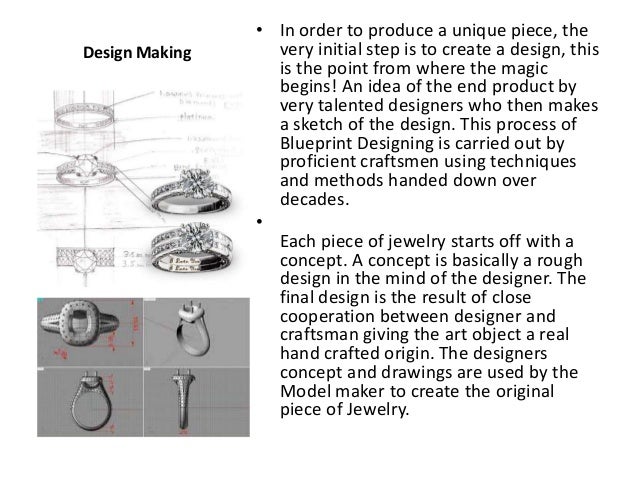

2. Design and Prototyping:

The creative heart of jewellery manufacturing beats within the design phase. Skilled designers translate artistic visions into tangible blueprints, meticulously crafting sketches and 3D models that capture the essence of the desired piece. This stage involves collaboration with clients, understanding their preferences and translating them into unique designs. Prototypes are then crafted, allowing for adjustments and refinements before mass production.

3. Casting and Molding:

For metal jewellery, the casting process transforms molten metal into precise shapes. This involves creating molds from wax or other materials, which are then used to create the desired forms. Advanced casting techniques like lost-wax casting ensure intricate details and flawless execution.

4. Metalworking and Shaping:

Once the metal is cast, skilled craftspeople manipulate it using various techniques like forging, rolling, and hammering to achieve the desired shapes and textures. This stage requires precision, dexterity, and a deep understanding of metal properties.

5. Gem Setting and Stone Cutting:

Gemstones, the heart of many jewellery pieces, require meticulous setting and cutting. Gem cutters employ specialized tools and techniques to enhance the brilliance and sparkle of precious stones, while setters use various methods to secure them into the metal framework, ensuring both durability and aesthetic appeal.

6. Finishing and Polishing:

The final stages of jewellery manufacturing involve refining the piece to perfection. This includes cleaning, polishing, and finishing techniques that enhance the piece’s luster and brilliance. Skilled artisans meticulously remove imperfections, ensuring a smooth, polished, and aesthetically pleasing finish.

7. Quality Control and Inspection:

Throughout the manufacturing process, stringent quality control measures are employed to ensure the highest standards. Skilled inspectors meticulously examine each piece, verifying its compliance with design specifications, material integrity, and craftsmanship. This ensures that every piece leaving the manufacturer’s hands meets the highest quality standards.

The Significance of Jewellery Manufacturers in the Global Industry

Jewellery manufacturers play a pivotal role in shaping the global jewellery industry, contributing to its economic vitality and cultural significance. Their contributions extend far beyond the creation of beautiful pieces, impacting various aspects of the industry:

1. Economic Contribution:

Jewellery manufacturing is a significant contributor to the global economy, providing employment opportunities and driving economic growth. From small-scale workshops to large-scale production facilities, the industry sustains a vast network of workers, artisans, and suppliers.

2. Cultural Preservation:

Jewellery manufacturing plays a crucial role in preserving cultural heritage and traditions. Many manufacturers specialize in crafting traditional jewellery styles, ensuring the continuity of these art forms and their cultural significance.

3. Innovation and Design:

Jewellery manufacturers constantly push the boundaries of design and innovation, introducing new trends and styles that shape the industry’s evolution. Their creativity and technical expertise drive the development of new materials, techniques, and designs, keeping the jewellery world vibrant and dynamic.

4. Sustainability and Ethical Sourcing:

Increasingly, jewellery manufacturers are embracing sustainability and ethical sourcing practices. They prioritize using recycled materials, reducing waste, and ensuring the ethical treatment of workers and the environment. These efforts promote responsible practices within the industry, contributing to a more sustainable future.

5. Global Trade and Commerce:

Jewellery manufacturing fosters global trade and commerce, connecting artisans and designers across continents. Manufacturers export their creations worldwide, sharing their artistry and craftsmanship with a global audience.

FAQs by Jewellery Manufacturers

1. What are the most common types of jewellery manufactured?

Jewellery manufacturers produce a vast array of pieces, ranging from simple earrings and necklaces to intricate rings, bracelets, and pendants. Popular categories include:

- Fine Jewellery: Crafted from precious metals like gold, silver, and platinum, often incorporating gemstones and pearls.

- Fashion Jewellery: Made from less expensive materials like brass, copper, and alloys, often featuring synthetic stones or glass beads.

- Custom Jewellery: Designed and crafted according to individual specifications, offering personalized expressions of style and sentiment.

2. What are the different metal alloys used in jewellery manufacturing?

Jewellery manufacturers utilize a wide range of metal alloys to achieve specific properties like durability, color, and affordability. Common alloys include:

- Gold Alloys: Karat gold (14K, 18K, 22K) is a mixture of gold and other metals like copper, silver, or nickel, influencing its color and hardness.

- Silver Alloys: Sterling silver (92.5% silver) is a popular choice for its affordability and brilliance.

- Platinum Alloys: Platinum is a highly durable and hypoallergenic metal, often alloyed with other metals to enhance its properties.

3. How do I choose a reputable jewellery manufacturer?

Selecting a reputable jewellery manufacturer is crucial for ensuring quality, ethical sourcing, and reliable service. Consider these factors:

- Experience and Expertise: Look for manufacturers with a proven track record and expertise in the desired jewellery style.

- Quality Control: Ensure the manufacturer implements stringent quality control measures, guaranteeing the integrity of their products.

- Ethical Sourcing: Inquire about their commitment to ethical sourcing practices, ensuring responsible sourcing of materials and fair labor conditions.

- Customer Service: Choose a manufacturer with excellent customer service, providing clear communication, timely responses, and a commitment to customer satisfaction.

4. What are the latest trends in jewellery manufacturing?

The jewellery industry is constantly evolving, driven by emerging trends and consumer preferences. Current trends include:

- Sustainable and Ethical Jewellery: Increasing demand for eco-friendly materials and sustainable manufacturing practices.

- Minimalist Designs: Simple, elegant pieces with clean lines and subtle details.

- Statement Pieces: Bold and eye-catching designs that make a statement.

- Personalized Jewellery: Customized pieces that reflect individual style and stories.

- Vintage and Retro Styles: Revival of classic and timeless designs from past eras.

Tips by Jewellery Manufacturers

1. Invest in Quality Materials: The foundation of any exquisite piece of jewellery lies in the quality of its materials. Choosing high-quality precious metals, gemstones, and other materials ensures durability, brilliance, and lasting value.

2. Embrace Innovation and Design: Stay ahead of the curve by embracing new design trends and exploring innovative techniques. Continuously refine your skills and seek inspiration from diverse sources.

3. Prioritize Sustainability: Implement sustainable practices throughout the manufacturing process, reducing waste, minimizing environmental impact, and sourcing materials ethically.

4. Foster Strong Customer Relationships: Build trust and loyalty by providing excellent customer service, offering personalized experiences, and responding to customer needs with care.

5. Embrace Technology: Leverage technology to enhance efficiency, streamline processes, and improve communication. Explore digital design tools, online marketplaces, and marketing strategies to reach a wider audience.

Conclusion by Jewellery Manufacturers

Jewellery manufacturing is a multifaceted industry that combines artistry, technical expertise, and a commitment to quality. From sourcing raw materials to crafting intricate designs, the journey of creating exquisite jewellery demands meticulous attention to detail and a passion for the craft. By embracing innovation, prioritizing sustainability, and fostering strong customer relationships, jewellery manufacturers can continue to shape the industry’s future, creating beautiful and enduring pieces that adorn lives and celebrate timeless beauty.

Closure

Thus, we hope this article has provided valuable insights into The Art and Science of Jewellery Manufacturing: A Comprehensive Guide. We hope you find this article informative and beneficial. See you in our next article!